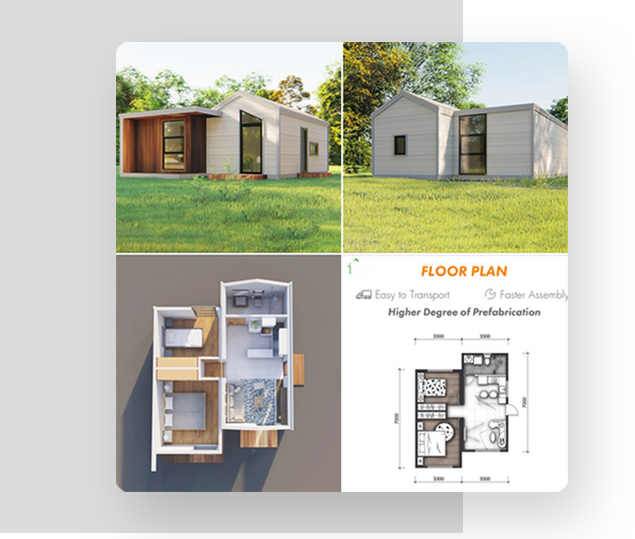

Quacent is a manufacturer and supplier of SIP panels and SIP precast wood building systems for residential construction.

Passive House is a building standard that combines ultra-low energy demand with high comfort, health, and construction quality. With Quacent SIPs (Structural Insulated Panels), you can build quickly, achieving a continuous airtight and highly insulated envelope—the cornerstone of every Passive House design

Passive House is a performance-based building standard developed by the Passive House Institute (PHI). Core requirements include:

Result: very low energy bills, draft-free spaces, quiet and stable indoor temperatures, and excellent building physics

SIPs are sandwich panels with structural facings and an insulating core. In one installation step, they provide structure + insulation + airtightness

Advantages for Passive House:

● Define certification goal (Classic, Plus, Premium). ● Optimize orientation, form factor, and glazing ratios. ● Create PHPP model using Quacent assemblies (U-values, ψ-values, shading, ventilation)

● Ensure continuous insulation and airtight layers ● Define an airtightness plan (sealing tapes, membranes, caulking. ● Address thermal bridges with detail calculations (foundation, windows, beams)

● Triple glazing, low Uw ≤ 0.8 W/m²·K, warm edge spacers. ● Thermally insulated installation frames. ● Positioned within the insulation layer for optimal performance.

● Balanced ventilation with ≥ 80% heat recovery efficiency. ● Compact low-temperature heating/cooling (e.g. heat pump). ● Airtight penetrations and service cavity for installations.

● Blower door test (target ≤ 0.4 h⁻¹ to allow margin). ● IR thermography, on-site inspections, and installation checklists. ● As-built PHPP verification and commissioning reports.

● Exterior finish (cladding, render system, or panels) ● Ventilated cavity ● SIP wall panel (165–310 mm) ● Airtight layer (sealing tapes, gaskets) ● Service cavity (40–60 mm, insulated) ● Interior finish (gypsum, gypsum fiber, or other)

● External roofing layer (tiles, membrane, or standing seam) ● SIP roof panel with continuous insulation ● Airtight joints and sealed penetrations ● Interior finish (fire-rated board, acoustic panel, or exposed finish

● Energy: extremely low heating/cooling demand → smaller HVAC systems, lower bills. ● Thermal comfort: no cold spots or drafts; stable surface temperatures ● Acoustics: airtight shell + mass-spring effect reduce external noise. ● Health: continuous fresh air supply through HRV systems.

● Energy demand: Passive House goes far beyond minimum energy codes. ● Envelope quality: stricter on airtightness and thermal bridging. ● Comfort: measurable improvements in indoor temperature stability and air quality. ● Verification: based on PHPP modeling + blower door testing, not just simulations

1. Feasibility Study – program, location, budget.

2. PHPP Concept Modeling – U-/ψ-values, glazing, shading, ventilation, iterations.

3. Detailing & Shop Drawings – CNC files, airtightness plan, service cavity strategy.

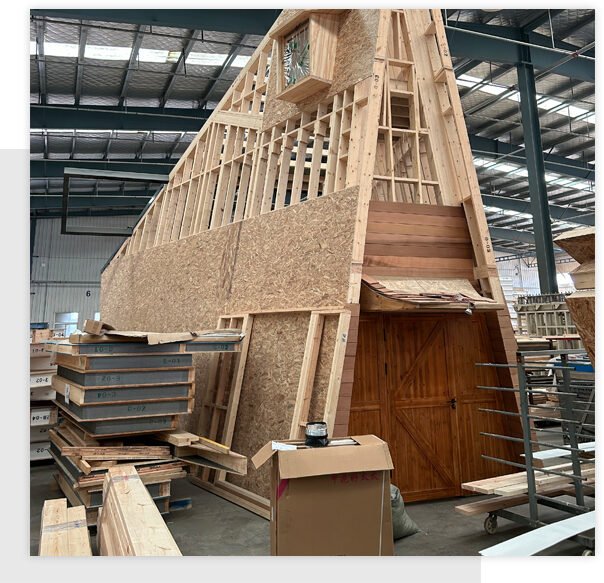

4. Prefabrication & Logistics – production, packaging by assembly sequence, shipping.

5. On-site Assembly & QA – training, airtightness checks, blower door testing.

6. Handover & Certification – final PHPP, documentation, and support for Passive House certification if desired.

Disclaimer: Performance values (U-values, ψ-values, airtightness rates, efficiencies) are

indicative. Final performance is determined per project via PHPP modeling, detailed

calculations, and on-site testing.